A Comprehensive Guide to MAPP Gas: Its Uses, Benefits, and Safety Considerations

Related Articles: A Comprehensive Guide to MAPP Gas: Its Uses, Benefits, and Safety Considerations

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to A Comprehensive Guide to MAPP Gas: Its Uses, Benefits, and Safety Considerations. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

A Comprehensive Guide to MAPP Gas: Its Uses, Benefits, and Safety Considerations

MAPP gas, an acronym for "MethylAcetylene-PropadienePropane," is a fuel gas commonly used in various industrial and commercial applications. It is a highly versatile and efficient fuel source, offering numerous benefits over other alternatives. This article provides a detailed exploration of MAPP gas, delving into its composition, properties, uses, safety protocols, and its significance in diverse industries.

Understanding the Composition and Properties of MAPP Gas:

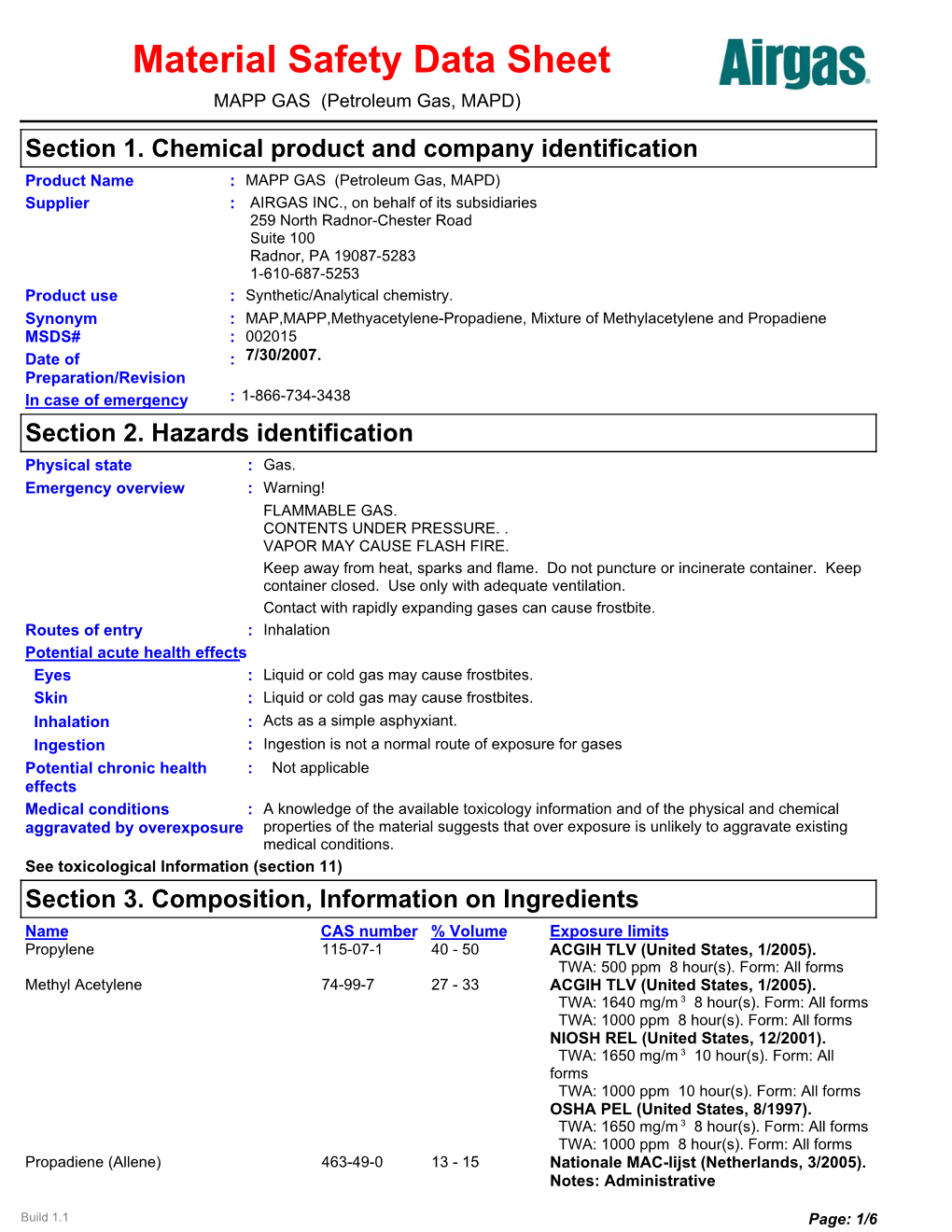

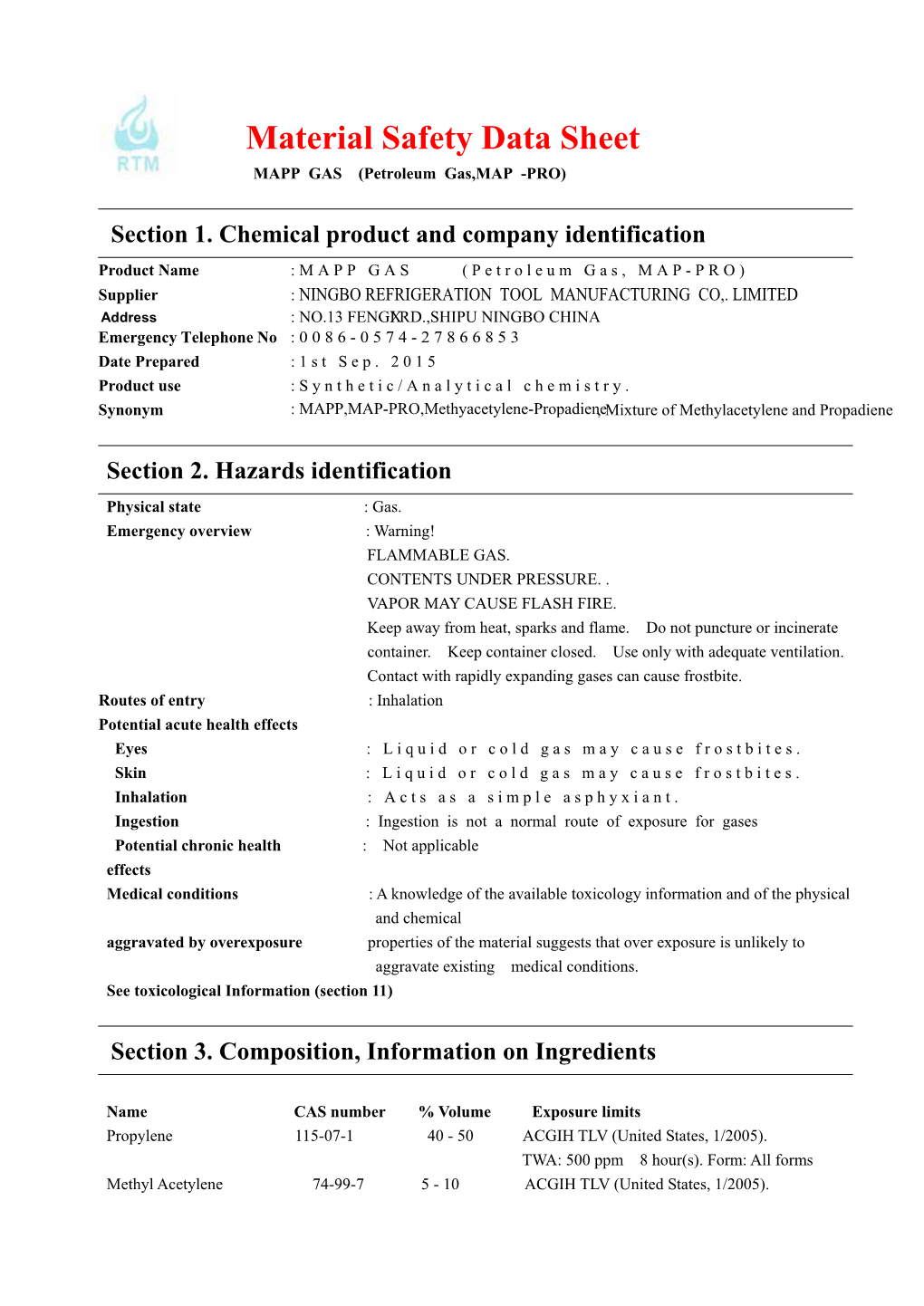

MAPP gas is a blend of hydrocarbons, primarily consisting of methylacetylene (propyne), propadiene, and propane. This unique composition gives MAPP gas its distinctive characteristics:

- High Heating Value: MAPP gas boasts a significantly higher heating value than propane, reaching approximately 2,500 BTU per cubic foot. This translates to greater heat output and faster heating times, making it ideal for applications demanding intense heat.

- Lower Flame Temperature: Compared to acetylene, MAPP gas exhibits a lower flame temperature, reducing the risk of material distortion or damage caused by excessive heat. This characteristic makes it suitable for delicate soldering and brazing tasks.

- Wide Operating Range: MAPP gas can be used over a broader range of pressures and temperatures compared to acetylene, offering greater flexibility in various applications.

- Lower Pressure Requirements: MAPP gas operates at lower pressures than acetylene, simplifying the design and maintenance of equipment and reducing the risk of leaks or accidents.

Applications of MAPP Gas:

MAPP gas finds applications in diverse industries, including:

- Metalworking: MAPP gas is widely used in metalworking for tasks such as brazing, soldering, cutting, and heating. Its high heating value and lower flame temperature make it suitable for a wide range of metal types, including copper, brass, and stainless steel.

- Construction: In construction, MAPP gas is employed for heating and thawing frozen pipes, as well as for melting asphalt and other construction materials. Its versatility and portability make it a valuable tool for on-site applications.

- Industrial Maintenance: MAPP gas plays a crucial role in industrial maintenance, facilitating tasks like pipefitting, welding, and repair work. Its high heat output and ease of use make it an efficient solution for various maintenance needs.

- Other Applications: MAPP gas finds applications in various other fields, including heating, plumbing, and automotive repair. Its versatility and efficiency make it a valuable tool for diverse tasks.

Safety Considerations When Using MAPP Gas:

While MAPP gas offers numerous benefits, it is crucial to prioritize safety when handling and using it. Here are some essential safety considerations:

- Storage and Handling: MAPP gas cylinders should be stored in a well-ventilated area, away from heat sources and direct sunlight. Always handle cylinders with care, using proper lifting techniques and protective gear.

- Ventilation: Ensure adequate ventilation when using MAPP gas, as it produces combustion byproducts that can be harmful if inhaled.

- Fire Hazards: MAPP gas is highly flammable and should be handled with caution. Avoid using it near open flames or ignition sources.

- Personal Protective Equipment (PPE): Always wear appropriate PPE when working with MAPP gas, including safety glasses, gloves, and fire-resistant clothing.

- Regular Inspection: Regularly inspect MAPP gas cylinders and equipment for leaks or damage. Replace damaged or faulty equipment promptly.

- Training and Education: Ensure all personnel working with MAPP gas receive adequate training on safe handling, storage, and use practices.

Benefits of Using MAPP Gas:

The unique properties of MAPP gas offer several advantages over other fuel gas alternatives:

- Increased Productivity: MAPP gas’s high heating value enables faster heating and melting times, leading to increased productivity and efficiency in various applications.

- Improved Quality: The lower flame temperature of MAPP gas reduces the risk of overheating and distortion, resulting in higher quality work and fewer rejects.

- Cost-Effectiveness: MAPP gas offers a cost-effective solution for various applications, as its high heating value and efficiency reduce fuel consumption and overall costs.

- Versatility: MAPP gas is a versatile fuel source suitable for a wide range of applications, making it a valuable asset for diverse industries.

FAQs about MAPP Gas:

1. What are the differences between MAPP gas and propane?

MAPP gas has a higher heating value than propane, resulting in faster heating times and greater heat output. It also has a lower flame temperature, making it ideal for applications requiring precise heat control.

2. Is MAPP gas safe to use?

MAPP gas is safe to use when handled properly and with appropriate safety precautions. Always follow manufacturer instructions and safety guidelines.

3. What are the potential risks associated with MAPP gas?

MAPP gas is flammable and can cause burns or fires if not handled carefully. It is also toxic if inhaled and can cause respiratory problems.

4. What are the proper storage and handling procedures for MAPP gas cylinders?

MAPP gas cylinders should be stored in a well-ventilated area, away from heat sources and direct sunlight. Always handle cylinders with care, using proper lifting techniques and protective gear.

5. What type of equipment is needed to use MAPP gas?

MAPP gas requires specialized equipment, including a regulator, torch, and hoses designed for its specific properties.

Tips for Using MAPP Gas Effectively:

- Proper Cylinder Selection: Choose the appropriate cylinder size based on the application’s requirements.

- Regular Equipment Maintenance: Regularly inspect and maintain MAPP gas equipment to ensure its safe and efficient operation.

- Proper Torch Adjustment: Adjust the flame size and temperature according to the specific task.

- Use Protective Gear: Always wear appropriate PPE when working with MAPP gas.

- Follow Manufacturer Instructions: Adhere to the manufacturer’s instructions and safety guidelines for all MAPP gas equipment and applications.

Conclusion:

MAPP gas is a highly efficient and versatile fuel source with numerous applications in diverse industries. Its unique properties, including high heating value, lower flame temperature, and wide operating range, offer significant advantages over other fuel gas alternatives. However, it is crucial to prioritize safety when handling and using MAPP gas, adhering to proper storage, handling, and use practices. By understanding its characteristics, benefits, and safety considerations, individuals and organizations can effectively leverage the power of MAPP gas for various tasks while ensuring a safe and productive work environment.

Closure

Thus, we hope this article has provided valuable insights into A Comprehensive Guide to MAPP Gas: Its Uses, Benefits, and Safety Considerations. We hope you find this article informative and beneficial. See you in our next article!