A Comprehensive Guide to MAPP Gas Kits: Understanding Their Applications, Benefits, and Safety Considerations

Related Articles: A Comprehensive Guide to MAPP Gas Kits: Understanding Their Applications, Benefits, and Safety Considerations

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to A Comprehensive Guide to MAPP Gas Kits: Understanding Their Applications, Benefits, and Safety Considerations. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

A Comprehensive Guide to MAPP Gas Kits: Understanding Their Applications, Benefits, and Safety Considerations

Introduction

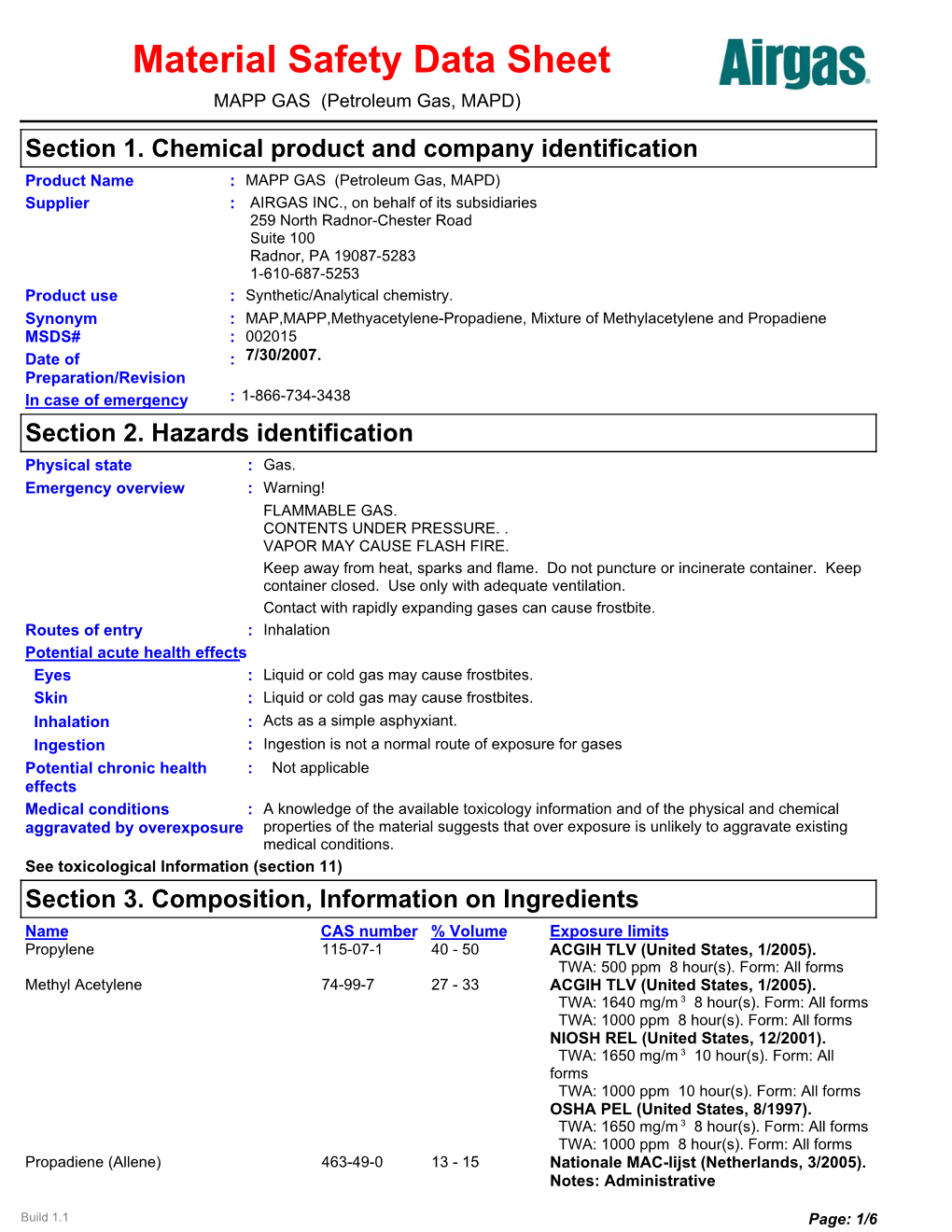

MAPP gas, short for "methyl acetylene propadiene," is a fuel gas widely utilized for various applications, including brazing, soldering, welding, and heating. MAPP gas kits, which comprise a gas cylinder, a regulator, and a torch, offer a versatile and efficient means to accomplish these tasks. This article delves into the intricacies of MAPP gas kits, exploring their composition, functionalities, and safety protocols, along with their advantages and potential drawbacks.

Understanding MAPP Gas

MAPP gas is a highly combustible mixture of hydrocarbons, primarily methylacetylene and propadiene, with a small percentage of other gases like propane and butane. It is renowned for its high BTU content, exceeding that of propane and natural gas, making it a powerful heat source. MAPP gas also exhibits a higher flame temperature than propane, reaching up to 3,700°F, which facilitates faster heating and more efficient metal working.

Components of a MAPP Gas Kit

A typical MAPP gas kit encompasses the following components:

-

MAPP Gas Cylinder: The cylinder stores the compressed MAPP gas. It is usually made from steel and features a valve for regulating gas flow. The size of the cylinder varies depending on the application and the volume of gas required.

-

Regulator: The regulator controls the gas pressure, reducing it from the high pressure inside the cylinder to a safe working pressure for the torch. Regulators typically have a pressure gauge to monitor the output pressure.

-

Torch: The torch is the device that utilizes the MAPP gas to generate a flame. It consists of a handle, a nozzle, and a mixing chamber where the gas mixes with air. Different types of torches are available, each suited for specific applications.

Applications of MAPP Gas Kits

MAPP gas kits find applications in various industries and DIY projects, owing to their versatility and efficiency. Some common applications include:

-

Brazing and Soldering: MAPP gas’s high flame temperature makes it ideal for brazing and soldering copper, brass, and other metals. It allows for faster heating and stronger joints.

-

Welding: While MAPP gas is not suitable for welding thick metals, it can be used for welding thinner metals, particularly in situations where portability and ease of use are crucial.

-

Heating: MAPP gas is commonly used for heating applications, such as thawing frozen pipes, removing paint, and even cooking.

-

DIY Projects: MAPP gas kits are popular among DIY enthusiasts for projects like plumbing repairs, metal fabrication, and automotive repairs.

Advantages of Using MAPP Gas Kits

MAPP gas kits offer several advantages over other fuel gas options, including:

-

High BTU Content: The high BTU content of MAPP gas translates to intense heat output, facilitating faster heating and more efficient metal working.

-

High Flame Temperature: MAPP gas boasts a higher flame temperature compared to propane, enabling faster melting and better penetration for brazing and soldering.

-

Versatility: MAPP gas kits can be used for a wide range of applications, from brazing and soldering to heating and DIY projects.

-

Portability: MAPP gas kits are relatively portable, making them convenient for on-site work and projects where access to electricity is limited.

Disadvantages and Safety Considerations

While MAPP gas kits offer numerous benefits, they also come with potential drawbacks and safety considerations:

-

Toxicity: MAPP gas is highly flammable and can be toxic if inhaled. Proper ventilation is crucial when working with MAPP gas to avoid inhaling fumes.

-

Risk of Burns: The high flame temperature poses a risk of severe burns if not handled carefully. Always wear appropriate protective gear, including gloves, safety glasses, and fire-resistant clothing.

-

Pressure Regulation: The high pressure inside the MAPP gas cylinder requires careful pressure regulation. Improper regulation can lead to dangerous situations.

-

Cylinder Handling: MAPP gas cylinders should be handled with care to prevent damage or leaks. Always secure the cylinder properly and avoid dropping or mishandling it.

FAQs Regarding MAPP Gas Kits

Q: What is the difference between MAPP gas and propane?

A: MAPP gas has a higher BTU content and flame temperature than propane, making it more efficient for brazing, soldering, and certain welding applications.

Q: Is MAPP gas safe to use indoors?

A: It is generally not recommended to use MAPP gas indoors due to the risk of fire and toxic fumes. Adequate ventilation is crucial for safe indoor use.

Q: How do I dispose of an empty MAPP gas cylinder?

A: Empty MAPP gas cylinders should be returned to a certified gas supplier for proper disposal. Do not attempt to dispose of them in regular trash or by puncturing them.

Q: What are the signs of a leaking MAPP gas cylinder?

A: Signs of a leaking MAPP gas cylinder include a hissing sound, a strong gas odor, and condensation forming on the cylinder. If you suspect a leak, evacuate the area immediately and contact a gas supplier.

Tips for Using MAPP Gas Kits Safely and Effectively

-

Read the Instructions: Always read and understand the manufacturer’s instructions before using a MAPP gas kit.

-

Wear Protective Gear: Wear appropriate protective gear, including gloves, safety glasses, and fire-resistant clothing.

-

Proper Ventilation: Ensure adequate ventilation when working with MAPP gas to prevent the accumulation of toxic fumes.

-

Regular Cylinder Inspection: Inspect the MAPP gas cylinder for damage or leaks before each use.

-

Secure Cylinder: Always secure the MAPP gas cylinder properly to prevent it from falling or being knocked over.

-

Avoid Contact with Flammables: Keep MAPP gas cylinders and torches away from flammable materials.

-

Proper Storage: Store MAPP gas cylinders in a cool, dry, and well-ventilated area, away from direct sunlight and heat sources.

Conclusion

MAPP gas kits offer a versatile and efficient solution for various applications, from brazing and soldering to heating and DIY projects. Their high BTU content and flame temperature provide superior performance compared to propane. However, it is crucial to prioritize safety when working with MAPP gas, as it is highly flammable and toxic if inhaled. By adhering to safety protocols and following the manufacturer’s instructions, users can leverage the benefits of MAPP gas kits while minimizing risks.

Closure

Thus, we hope this article has provided valuable insights into A Comprehensive Guide to MAPP Gas Kits: Understanding Their Applications, Benefits, and Safety Considerations. We hope you find this article informative and beneficial. See you in our next article!