The 2000 Map Gas Shortage: A Case Study in Supply Chain Vulnerability

Related Articles: The 2000 Map Gas Shortage: A Case Study in Supply Chain Vulnerability

Introduction

With great pleasure, we will explore the intriguing topic related to The 2000 Map Gas Shortage: A Case Study in Supply Chain Vulnerability. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The 2000 Map Gas Shortage: A Case Study in Supply Chain Vulnerability

The year 2000 witnessed a significant disruption in the supply of map gas, a crucial component in various industrial processes. This shortage, while not widely publicized, had a profound impact on industries reliant on this gas, highlighting the vulnerabilities inherent in global supply chains. This article delves into the causes, consequences, and lessons learned from the 2000 map gas shortage, providing a comprehensive analysis of this critical event.

Understanding Map Gas and its Importance

Map gas, a mixture of propane and butane, serves as a vital fuel source in numerous industrial applications. It is commonly used in:

- Metalworking: Map gas fuels cutting, welding, and brazing processes, crucial for manufacturing and construction.

- Glassblowing: The precise flame control offered by map gas is essential for shaping and manipulating glass in various industries.

- Food Processing: Map gas is utilized in food processing, particularly for sterilizing equipment and packaging.

- Chemical Production: Certain chemical manufacturing processes rely on map gas as a fuel source or reactant.

The widespread use of map gas makes it a critical component of numerous economic sectors. Any disruption in its supply chain can have cascading effects across multiple industries.

The Genesis of the 2000 Map Gas Shortage

The 2000 map gas shortage was a complex event stemming from a confluence of factors:

- Increased Demand: Rapid economic growth, particularly in emerging markets, led to a surge in demand for map gas, exceeding available supply.

- Production Bottlenecks: Existing map gas production facilities struggled to keep pace with the escalating demand, leading to production delays and shortages.

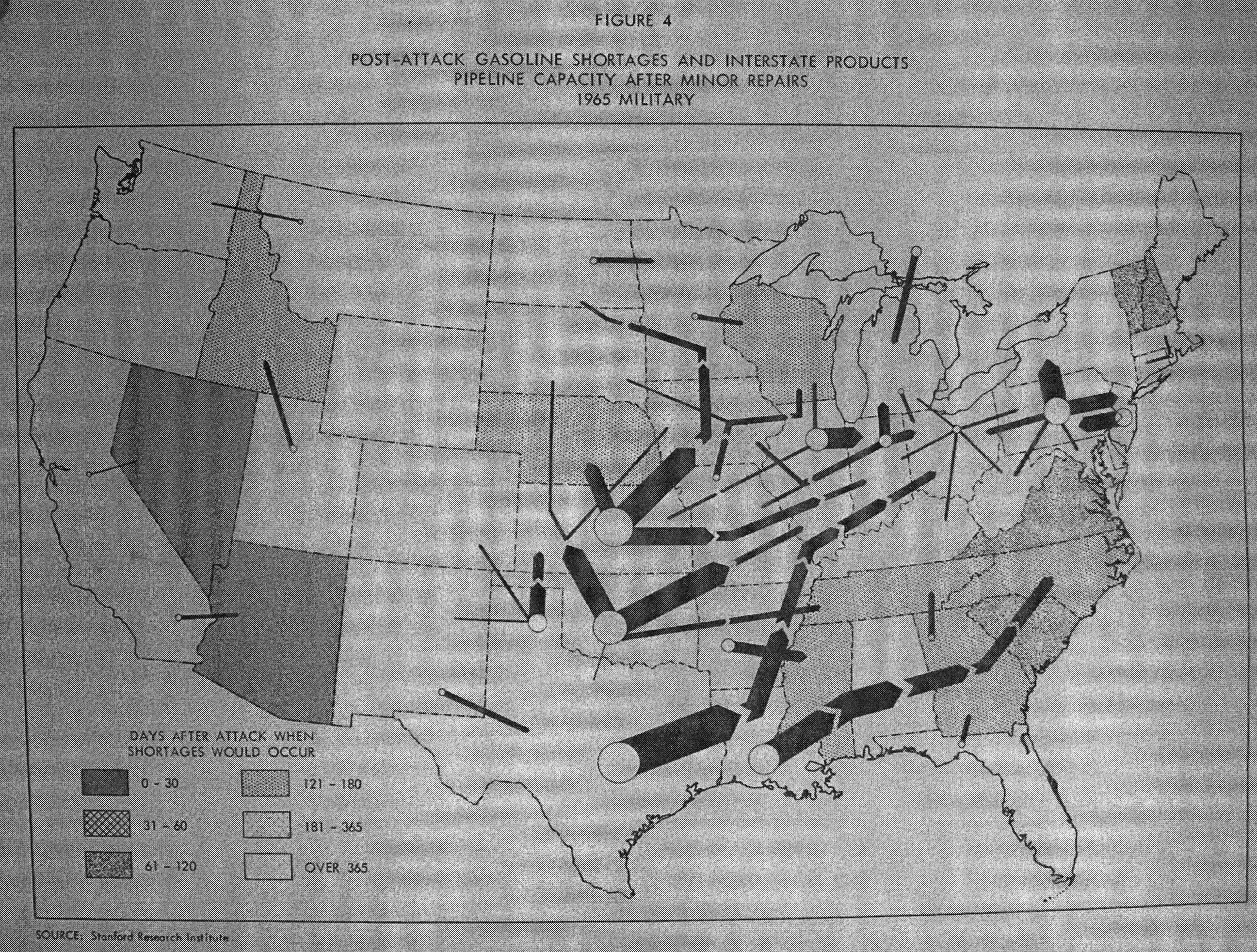

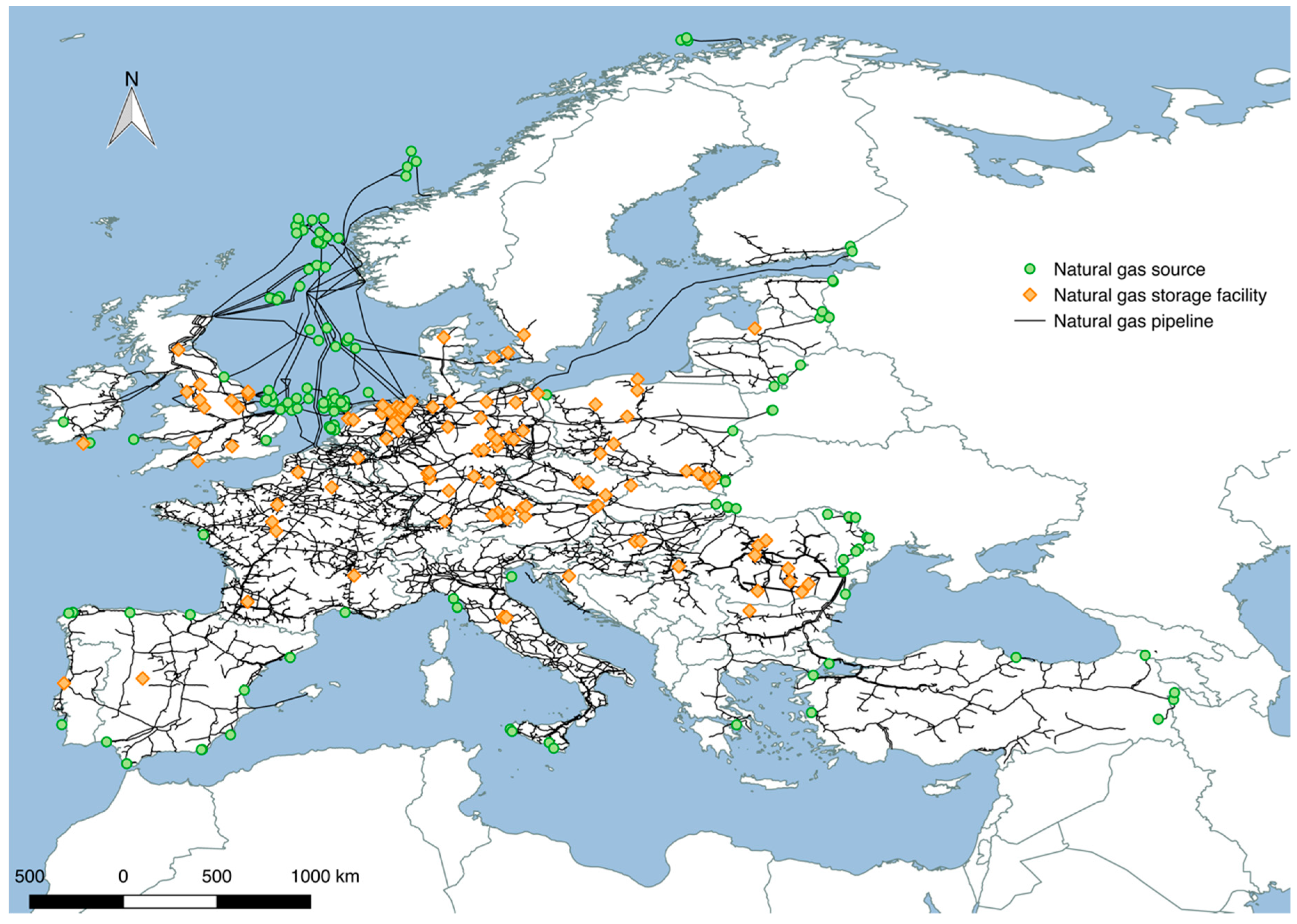

- Transportation Constraints: Infrastructure limitations, particularly in developing countries, hampered the efficient transportation of map gas, exacerbating the supply-demand imbalance.

- Geopolitical Factors: International conflicts and trade restrictions impacted the flow of raw materials and finished map gas products, further complicating the situation.

These factors combined to create a perfect storm, leading to a significant shortage of map gas in 2000.

Consequences of the Shortage

The map gas shortage had significant consequences for various industries:

- Production Halts: Many industries, particularly those reliant on map gas for core operations, faced production halts or significant delays, impacting output and revenue.

- Price Volatility: The shortage led to a sharp increase in map gas prices, putting pressure on businesses and impacting their profitability.

- Supply Chain Disruptions: The shortage exposed the vulnerabilities of global supply chains, highlighting the need for diversification and contingency planning.

- Economic Impact: The combined effects of production halts, price increases, and supply chain disruptions had a ripple effect across economies, impacting employment and overall economic growth.

Lessons Learned from the 2000 Map Gas Shortage

The 2000 map gas shortage served as a stark reminder of the importance of robust supply chain management and the potential consequences of disruptions:

- Diversification of Supply: Reliance on a single source of supply is a significant risk. Diversifying sourcing strategies and exploring alternative fuel options can mitigate supply chain vulnerabilities.

- Contingency Planning: Businesses need to develop contingency plans to address potential disruptions in critical supplies. This includes stockpiling, exploring alternative suppliers, and adapting production processes.

- Enhanced Infrastructure: Investment in infrastructure, particularly transportation and logistics, is crucial for ensuring efficient and reliable supply chains.

- Collaboration and Information Sharing: Open communication and collaboration among industry stakeholders, including suppliers, manufacturers, and government agencies, are vital for effective crisis management.

FAQs about the 2000 Map Gas Shortage:

Q: What was the primary cause of the 2000 map gas shortage?

A: The shortage was a result of several factors, including increased demand, production bottlenecks, transportation constraints, and geopolitical factors.

Q: How did the shortage impact industries reliant on map gas?

A: The shortage led to production halts, price increases, supply chain disruptions, and ultimately, economic impacts across various sectors.

Q: What measures were taken to address the shortage?

A: Industries implemented various strategies, including diversifying supply sources, exploring alternative fuels, and adapting production processes.

Q: What lessons were learned from the 2000 map gas shortage?

A: The event highlighted the need for robust supply chain management, diversification of sources, contingency planning, and improved infrastructure.

Tips to Avoid Future Map Gas Shortages:

- Early Detection: Monitoring demand trends and potential supply chain disruptions is crucial for early intervention.

- Strategic Stockpiling: Maintaining adequate stockpiles of map gas can mitigate the impact of short-term supply disruptions.

- Alternative Fuel Exploration: Investigating alternative fuel sources and technologies can provide a safety net in case of shortages.

- Government Collaboration: Collaborating with government agencies to ensure stable map gas supply and address potential challenges is vital.

Conclusion

The 2000 map gas shortage was a significant event that exposed the vulnerabilities of global supply chains and the critical importance of map gas to various industries. The lessons learned from this event continue to be relevant today, emphasizing the need for proactive supply chain management, diversification, contingency planning, and collaboration to mitigate future disruptions. As the world becomes increasingly interconnected, ensuring a reliable and sustainable supply of critical resources like map gas will be essential for maintaining economic stability and growth.

Closure

Thus, we hope this article has provided valuable insights into The 2000 Map Gas Shortage: A Case Study in Supply Chain Vulnerability. We appreciate your attention to our article. See you in our next article!