The Crucial Role of MAP Gas in Industrial Applications

Related Articles: The Crucial Role of MAP Gas in Industrial Applications

Introduction

With enthusiasm, let’s navigate through the intriguing topic related to The Crucial Role of MAP Gas in Industrial Applications. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Crucial Role of MAP Gas in Industrial Applications

MAP gas, a blend of gases primarily composed of propane and methylacetylene-propadiene (MAPP), stands as a versatile and indispensable tool in various industrial applications. Its unique properties, derived from the careful composition of its constituents, make it an ideal choice for a wide range of tasks, particularly those involving high-temperature applications.

Understanding the Composition and Properties of MAP Gas

MAP gas is a carefully engineered mixture of gases, typically comprising approximately 50% propane and 50% MAPP. This specific blend results in a gas with a distinct set of properties that distinguish it from pure propane or other fuel gases.

- Higher BTU Content: MAP gas boasts a significantly higher British thermal unit (BTU) content compared to propane. This translates to a greater amount of heat generated per unit of gas, making it a more efficient fuel source for high-temperature applications.

- Lower Flame Temperature: Despite its higher BTU content, MAP gas produces a slightly lower flame temperature than pure propane. This characteristic is crucial in specific applications where excessive heat can be detrimental.

- Improved Flame Stability: The presence of MAPP enhances the flame stability of the gas mixture. This ensures a consistent and reliable flame, reducing the risk of blowouts or inconsistencies during operation.

- Increased Thermal Efficiency: The unique blend of propane and MAPP results in a more efficient heat transfer, leading to faster heating times and improved overall thermal efficiency.

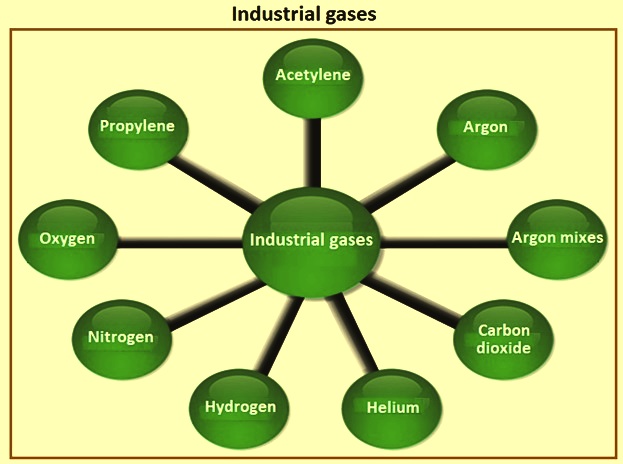

Applications of MAP Gas in Diverse Industries

The remarkable properties of MAP gas make it a highly valuable resource across various industrial sectors. Its ability to generate high temperatures, maintain flame stability, and offer efficient heat transfer makes it ideal for a wide range of applications, including:

- Metalworking: MAP gas is widely used in metalworking operations such as cutting, welding, and brazing. Its high heat output and flame stability enable efficient and precise metalworking, ensuring high-quality results.

- Manufacturing: MAP gas finds its place in various manufacturing processes, including heat treating, soldering, and brazing. Its versatility and efficiency make it a preferred choice for manufacturers seeking high-quality and consistent results.

- Construction: In construction, MAP gas is employed for tasks like welding and cutting steel structures, providing a reliable and efficient solution for large-scale projects.

- Automotive Repair: MAP gas is a common tool in automotive repair shops, used for welding and brazing metal components, ensuring precise and durable repairs.

- Heating and Plumbing: MAP gas is also utilized in heating and plumbing applications, particularly for tasks requiring high temperatures, such as soldering pipes and heating water tanks.

Advantages of Using MAP Gas

The use of MAP gas offers several advantages over other fuel gases, making it a preferred choice in various industrial settings:

- Enhanced Productivity: The higher BTU content of MAP gas leads to faster heating and processing times, resulting in increased productivity and efficiency.

- Improved Quality: The consistent flame stability and efficient heat transfer of MAP gas ensure high-quality results in applications like welding, brazing, and heat treating.

- Cost-Effectiveness: While MAP gas may have a higher price per unit compared to propane, its higher BTU content and efficiency can result in overall cost savings by reducing gas consumption.

- Environmental Considerations: MAP gas is a cleaner-burning fuel compared to other options like acetylene, producing fewer emissions and contributing to a more sustainable industrial environment.

FAQs Regarding MAP Gas

1. What are the safety precautions associated with using MAP gas?

MAP gas is a flammable gas and should be handled with care. It is crucial to follow all safety guidelines outlined by the manufacturer and relevant authorities. These guidelines include:

- Proper storage: MAP gas cylinders should be stored in a well-ventilated area, away from heat and ignition sources.

- Secure handling: Cylinders should be handled with caution, ensuring they are properly secured and transported to prevent falls or damage.

- Appropriate ventilation: Adequate ventilation is essential during use to prevent the buildup of flammable gases.

- Fire extinguisher availability: A readily accessible fire extinguisher should be present in the work area for emergency situations.

2. How is MAP gas different from propane?

MAP gas differs from propane in its composition and properties. While both are primarily composed of hydrocarbons, MAP gas contains a significant proportion of MAPP, which contributes to its higher BTU content, lower flame temperature, and improved flame stability.

3. Is MAP gas suitable for all welding applications?

While MAP gas is a versatile welding gas, it is not suitable for all applications. For instance, it is not recommended for welding aluminum or other materials with low melting points due to its high heat output.

4. What are the common uses of MAP gas in the automotive industry?

MAP gas is frequently used in automotive repair shops for tasks such as:

- Welding exhaust systems: The high heat output and flame stability of MAP gas enable efficient and durable welding of exhaust components.

- Brazing suspension components: MAP gas is ideal for brazing suspension components, ensuring strong and reliable connections.

- Repairing body panels: MAP gas can be used to repair damaged body panels, ensuring a seamless and durable repair.

Tips for Effective Use of MAP Gas

- Use the right equipment: Ensure that the torch, regulator, and hoses are compatible with MAP gas to prevent leaks and ensure safe operation.

- Adjust the flame properly: Adjust the flame to the appropriate size and heat output for the specific application.

- Maintain a consistent flow: Maintain a steady gas flow during operation to ensure consistent flame stability and prevent blowouts.

- Inspect equipment regularly: Regularly inspect the torch, regulator, and hoses for any signs of damage or leaks.

- Follow safety precautions: Always prioritize safety by following the manufacturer’s guidelines and implementing proper safety practices.

Conclusion

MAP gas stands as a valuable and versatile tool in various industrial applications, offering a unique blend of properties that make it ideal for high-temperature operations. Its high BTU content, improved flame stability, and efficient heat transfer contribute to increased productivity, improved quality, and cost-effectiveness. By understanding the advantages and potential risks associated with MAP gas, industries can effectively utilize this essential resource to achieve optimal results while maintaining safety and sustainability.

![Classification of industrial gases processing [14]. Download Scientific Diagram](https://www.researchgate.net/profile/Yas_Alsultanny/publication/287708500/figure/download/fig2/AS:555427440099328@1509435629227/Classification-of-industrial-gases-processing-14.png)

Closure

Thus, we hope this article has provided valuable insights into The Crucial Role of MAP Gas in Industrial Applications. We thank you for taking the time to read this article. See you in our next article!