The Essential Role of Gas Nozzles in Precision Welding

Related Articles: The Essential Role of Gas Nozzles in Precision Welding

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to The Essential Role of Gas Nozzles in Precision Welding. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

- 1 Related Articles: The Essential Role of Gas Nozzles in Precision Welding

- 2 Introduction

- 3 The Essential Role of Gas Nozzles in Precision Welding

- 3.1 Understanding the Function of Gas Nozzles

- 3.2 Types of Gas Nozzles and Their Applications

- 3.3 The Importance of Choosing the Right Gas Nozzle

- 3.4 Benefits of Using Gas Nozzles in Welding

- 3.5 Frequently Asked Questions about Gas Nozzles

- 3.6 Tips for Using Gas Nozzles Effectively

- 3.7 Conclusion

- 4 Closure

The Essential Role of Gas Nozzles in Precision Welding

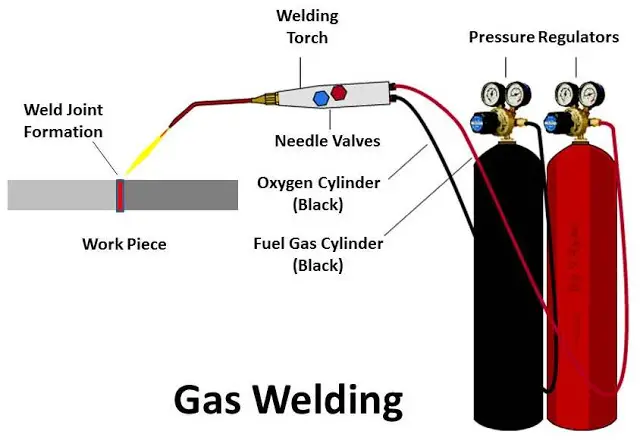

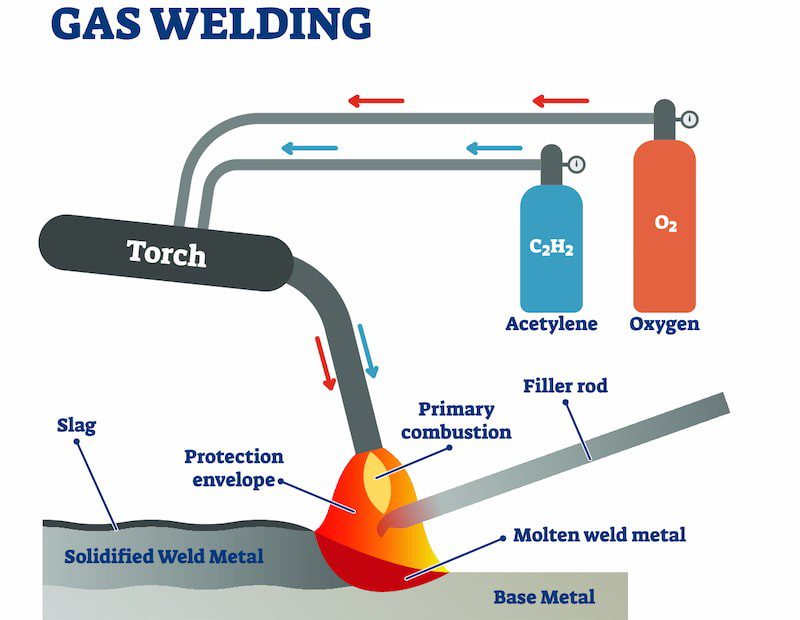

In the realm of welding, precision is paramount. The ability to control the flow of gas, the heat source, and the overall welding process is crucial for achieving strong, durable, and aesthetically pleasing welds. This is where gas nozzles play a critical role, acting as the bridge between the gas supply and the welding torch, ensuring the accurate and efficient delivery of gas to the welding area.

Understanding the Function of Gas Nozzles

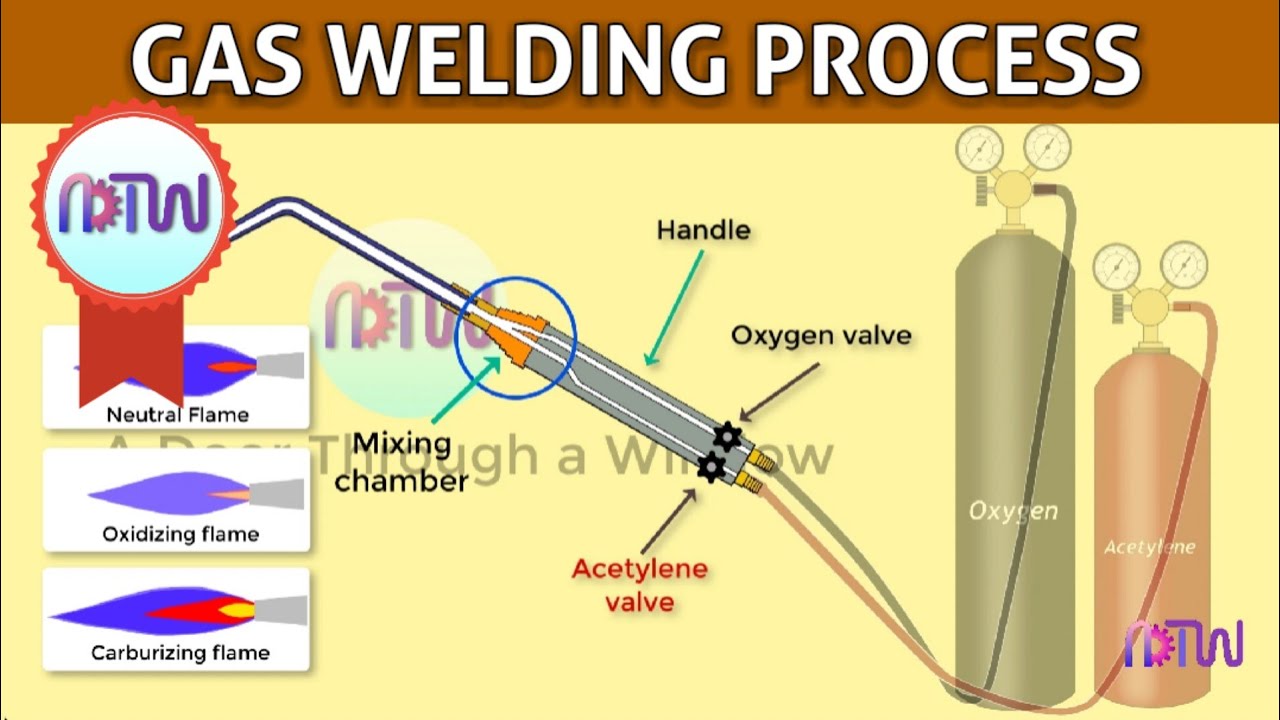

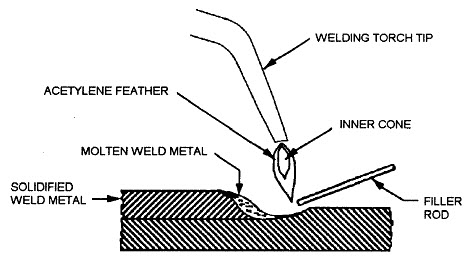

Gas nozzles are integral components of welding torches, responsible for channeling and directing the flow of shielding gas to the weld pool. This shielding gas, typically a mixture of argon, helium, or carbon dioxide, serves a critical function in protecting the molten weld metal from atmospheric contaminants, such as oxygen and nitrogen. These contaminants can compromise the weld’s integrity, leading to defects like porosity and cracking.

Gas nozzles are typically constructed from durable materials such as brass, copper, or stainless steel, ensuring resistance to high temperatures and corrosive gases. They are designed with specific internal geometries to optimize gas flow and distribution, ensuring a consistent and focused shield around the weld pool. The nozzle’s diameter and shape are crucial factors in determining the volume and pattern of gas flow, directly impacting the effectiveness of the shielding gas and the quality of the weld.

Types of Gas Nozzles and Their Applications

Gas nozzles are categorized based on their application and the type of welding process they are designed for. Some common types include:

-

Standard Gas Nozzles: These are universal nozzles suitable for various welding processes, including MIG (Gas Metal Arc Welding), TIG (Gas Tungsten Arc Welding), and plasma cutting. They offer a balanced gas flow and are ideal for general-purpose applications.

-

High-Flow Gas Nozzles: These nozzles are designed to handle larger volumes of gas, often used in high-amperage welding applications where a stronger shielding gas is required.

-

Specialty Gas Nozzles: These nozzles are tailored for specific welding processes or applications, such as robotic welding, submerged arc welding, or laser welding. They may feature unique designs to optimize gas flow and distribution for the specific requirements of the process.

-

Dual-Flow Gas Nozzles: These nozzles incorporate a separate gas flow path for the introduction of additional gases, such as nitrogen or oxygen, into the welding process. This feature allows for greater control over the weld pool and the creation of specialized welds.

The Importance of Choosing the Right Gas Nozzle

Selecting the appropriate gas nozzle is crucial for achieving optimal welding performance. Factors to consider include:

-

Welding Process: The specific welding process, such as MIG, TIG, or plasma cutting, will determine the type of gas nozzle required.

-

Gas Type and Flow Rate: The type of shielding gas and the desired flow rate will influence the nozzle’s size and design.

-

Welding Current: The welding current dictates the amount of heat generated, and the nozzle must be capable of handling the required gas flow for adequate shielding.

-

Joint Configuration: The geometry of the weld joint can influence the direction and distribution of gas flow, requiring a nozzle design that effectively shields the weld pool.

-

Material Type: The type of material being welded can impact the required shielding gas and flow rate, necessitating the selection of a suitable gas nozzle.

Benefits of Using Gas Nozzles in Welding

The use of gas nozzles in welding offers several significant benefits:

-

Enhanced Weld Quality: Proper shielding gas delivery protects the weld pool from contaminants, resulting in sound welds with minimal defects like porosity and cracking.

-

Increased Productivity: Consistent gas flow and accurate shielding enable faster welding speeds, improving overall productivity.

-

Reduced Material Waste: By minimizing defects, gas nozzles contribute to reduced material waste and scrap, improving overall cost efficiency.

-

Improved Safety: Adequate shielding gas protects the welder from harmful fumes and sparks, enhancing workplace safety.

-

Versatility: Gas nozzles are compatible with various welding processes and materials, offering versatility in welding applications.

Frequently Asked Questions about Gas Nozzles

1. What is the difference between a standard gas nozzle and a high-flow gas nozzle?

Standard gas nozzles are suitable for general-purpose welding applications, while high-flow nozzles are designed for high-amperage welding processes where larger volumes of gas are required for effective shielding.

2. How often should gas nozzles be replaced?

Gas nozzles should be inspected regularly for wear and tear, including signs of clogging, erosion, or damage. Replace nozzles as needed to ensure optimal gas flow and shielding.

3. Can I use a different type of gas nozzle for different welding processes?

While some gas nozzles may be compatible with multiple welding processes, it is generally recommended to use nozzles specifically designed for the intended application to ensure optimal performance.

4. How do I choose the right gas nozzle for my welding needs?

Consider the welding process, gas type and flow rate, welding current, joint configuration, and material type when selecting a gas nozzle. Consult with welding equipment manufacturers or suppliers for specific recommendations.

5. What are the safety precautions when using gas nozzles?

Ensure that the gas nozzle is securely attached to the welding torch and that the gas supply is properly regulated. Avoid touching the nozzle while it is hot, and use appropriate personal protective equipment, such as gloves and safety glasses.

Tips for Using Gas Nozzles Effectively

- Regularly inspect gas nozzles for wear and tear. Replace nozzles as needed to maintain optimal gas flow and shielding.

- Ensure the gas nozzle is securely attached to the welding torch. A loose connection can lead to gas leaks and inconsistent shielding.

- Adjust the gas flow rate according to the welding process and material type. Refer to the manufacturer’s instructions for recommended flow rates.

- Maintain a clean and dry gas nozzle. Clogging or contamination can affect gas flow and shielding effectiveness.

- Use appropriate personal protective equipment when handling gas nozzles.

Conclusion

Gas nozzles play a vital role in welding, ensuring the accurate and efficient delivery of shielding gas to the weld pool. By protecting the molten weld metal from atmospheric contaminants, gas nozzles contribute to the creation of strong, durable, and aesthetically pleasing welds. Understanding the different types of gas nozzles, their applications, and the importance of choosing the right nozzle is essential for achieving optimal welding performance. With proper selection, maintenance, and usage, gas nozzles can significantly enhance welding quality, productivity, and safety.

.jpeg)

Closure

Thus, we hope this article has provided valuable insights into The Essential Role of Gas Nozzles in Precision Welding. We appreciate your attention to our article. See you in our next article!