The Science of Food Preservation: Understanding the Role of Modified Atmosphere Packaging (MAP)

Related Articles: The Science of Food Preservation: Understanding the Role of Modified Atmosphere Packaging (MAP)

Introduction

With great pleasure, we will explore the intriguing topic related to The Science of Food Preservation: Understanding the Role of Modified Atmosphere Packaging (MAP). Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

- 1 Related Articles: The Science of Food Preservation: Understanding the Role of Modified Atmosphere Packaging (MAP)

- 2 Introduction

- 3 The Science of Food Preservation: Understanding the Role of Modified Atmosphere Packaging (MAP)

- 3.1 The Science Behind MAP: Creating an Ideal Environment

- 3.2 Applications of MAP: A Wide Range of Food Products

- 3.3 Advantages of MAP: A Comprehensive Overview

- 3.4 Considerations and Challenges in MAP

- 3.5 FAQs: Addressing Common Questions about MAP

- 3.6 Tips for Successful MAP Implementation

- 3.7 Conclusion: A Key Tool for Food Preservation

- 4 Closure

The Science of Food Preservation: Understanding the Role of Modified Atmosphere Packaging (MAP)

The modern world relies heavily on efficient food preservation methods to ensure food safety and minimize waste. One such method, Modified Atmosphere Packaging (MAP), has revolutionized how we store and consume a wide range of food products. This article delves into the science behind MAP, exploring its benefits, applications, and the crucial role it plays in maintaining food quality and extending shelf life.

The Science Behind MAP: Creating an Ideal Environment

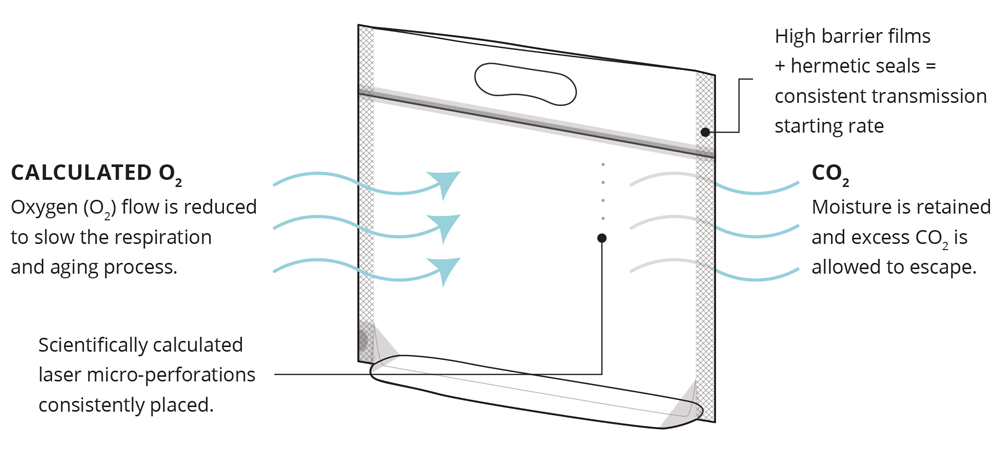

MAP involves altering the atmospheric composition within a package to create an environment that slows down the deterioration of food. This alteration typically involves reducing the oxygen content and increasing the levels of carbon dioxide or nitrogen.

Oxygen’s Role in Food Spoilage: Oxygen is a key contributor to food spoilage. It promotes the growth of aerobic bacteria, molds, and yeasts, leading to discoloration, off-flavors, and ultimately, food waste.

The Benefits of Modified Atmospheres: By reducing oxygen levels, MAP inhibits the growth of these spoilage organisms, significantly extending the shelf life of food products. The increased levels of carbon dioxide further contribute to preservation by inhibiting microbial growth and slowing down enzymatic reactions that cause food deterioration.

Types of Gases Used in MAP:

- Nitrogen (N2): A colorless, odorless, and inert gas, nitrogen displaces oxygen, creating an anaerobic environment that inhibits microbial growth. It is commonly used in packaging fresh produce, meat, and seafood.

- Carbon Dioxide (CO2): Carbon dioxide is a colorless, odorless gas with acidic properties. It inhibits microbial growth by lowering the pH of the product’s environment. It is frequently used in packaging meat, poultry, and bakery goods.

- Oxygen (O2): While oxygen is generally detrimental to food preservation, it is sometimes used in combination with other gases for specific applications. For instance, in some meat packaging, a small amount of oxygen is added to maintain a red color.

Applications of MAP: A Wide Range of Food Products

MAP is a versatile technology with applications across various food categories:

Fresh Produce: Fruits and vegetables are highly susceptible to spoilage due to their high water content and respiration rates. MAP helps maintain their freshness and quality by extending shelf life and reducing wilting and discoloration.

Meat and Poultry: MAP is widely used in the meat industry to extend the shelf life of fresh meat and poultry. The reduced oxygen levels inhibit the growth of bacteria, while the increased carbon dioxide helps maintain the red color and preserve the texture.

Seafood: Seafood is highly perishable due to its high moisture content and susceptibility to bacterial growth. MAP helps slow down spoilage by reducing oxygen levels and inhibiting bacterial growth, ensuring a longer shelf life and maintaining the freshness and flavor.

Bakery Products: MAP is used to extend the shelf life of baked goods, such as bread, cakes, and pastries. The reduced oxygen levels prevent the growth of mold and bacteria, while the increased carbon dioxide helps maintain the softness and freshness of the product.

Dairy Products: MAP can be used to extend the shelf life of dairy products, such as cheese and yogurt. The reduced oxygen levels inhibit the growth of bacteria and mold, preserving the flavor and texture of these products.

Other Applications: MAP is also employed in packaging processed foods, such as snacks, ready meals, and dried foods, to enhance shelf life and maintain quality.

Advantages of MAP: A Comprehensive Overview

The use of MAP offers numerous advantages for food producers and consumers alike:

Extended Shelf Life: The primary advantage of MAP is its ability to extend the shelf life of food products. This allows for reduced food waste, improved supply chain efficiency, and greater availability of fresh and high-quality food.

Improved Food Safety: By inhibiting the growth of spoilage organisms, MAP helps maintain food safety and reduce the risk of foodborne illnesses. This is particularly important for perishable foods that are susceptible to bacterial contamination.

Enhanced Product Quality: MAP helps maintain the quality and appearance of food products by reducing discoloration, wilting, and other forms of deterioration. This ensures that consumers enjoy the optimal flavor, texture, and appearance of the food.

Reduced Packaging Waste: MAP can contribute to a more sustainable food system by reducing the need for excessive packaging materials. This is because the modified atmosphere helps preserve food for longer, reducing the need for frequent repackaging.

Environmental Benefits: By reducing food waste and promoting sustainable packaging practices, MAP contributes to environmental sustainability by minimizing the impact of the food industry on natural resources.

Considerations and Challenges in MAP

While MAP offers significant advantages, it also presents some considerations and challenges:

Cost: The initial investment in MAP equipment and packaging materials can be relatively high. However, the long-term benefits of extended shelf life and reduced food waste can offset these costs.

Product Compatibility: Not all food products are suitable for MAP. Some products, such as those with high respiration rates or those that are sensitive to carbon dioxide, may not benefit from this technology.

Gas Permeability: The packaging material used in MAP must be impermeable to the gases used in the modified atmosphere. This is crucial to ensure that the desired gas composition is maintained within the package.

Regulation and Compliance: MAP practices are subject to regulatory oversight to ensure food safety and compliance with labeling requirements. Food producers must adhere to these regulations to ensure the safety and quality of their products.

FAQs: Addressing Common Questions about MAP

Q1: Is MAP safe for consumers?

A: MAP is a safe and widely accepted food preservation method. The gases used in MAP are generally recognized as safe (GRAS) by regulatory bodies, and the process itself does not pose any health risks to consumers.

Q2: How does MAP affect the nutritional value of food?

A: MAP generally has minimal impact on the nutritional value of food. However, it’s important to note that some vitamins and antioxidants may be sensitive to oxygen levels, so their levels might decline slightly over time.

Q3: What are the signs that a MAP-packaged food product has gone bad?

A: While MAP extends shelf life, it does not prevent spoilage indefinitely. Signs that a MAP-packaged food product has gone bad include discoloration, off-odors, changes in texture, and the presence of mold or bacteria.

Q4: Can I reuse MAP packaging for other products?

A: It is not recommended to reuse MAP packaging for other products. The packaging materials are designed specifically for the intended gas composition and may not be suitable for other products.

Q5: How can I tell if a product is packaged using MAP?

A: MAP packaging is often labeled with information about the modified atmosphere, such as the specific gases used or the shelf life extension provided by the technology.

Tips for Successful MAP Implementation

1. Choose the Right Packaging Material: The packaging material must be impermeable to the gases used in the modified atmosphere to ensure the desired gas composition is maintained.

2. Optimize Gas Composition: The optimal gas composition will vary depending on the specific food product. It’s essential to conduct testing to determine the best gas mix for each product.

3. Monitor Product Quality: Regular monitoring of product quality is crucial to ensure that the MAP process is effective in extending shelf life and maintaining quality.

4. Adhere to Regulatory Requirements: Food producers must adhere to all applicable regulations regarding MAP practices, including labeling requirements and food safety standards.

5. Educate Consumers: Consumers should be educated about the benefits of MAP and how to properly store and handle MAP-packaged food products.

Conclusion: A Key Tool for Food Preservation

Modified Atmosphere Packaging (MAP) is a critical tool in modern food preservation, offering numerous benefits for food producers and consumers. By extending shelf life, improving food safety, and enhancing product quality, MAP plays a vital role in reducing food waste, ensuring food security, and promoting a more sustainable food system. As technology continues to advance, MAP is poised to become even more sophisticated and widely adopted, further enhancing its role in preserving food and ensuring its availability for generations to come.

Closure

Thus, we hope this article has provided valuable insights into The Science of Food Preservation: Understanding the Role of Modified Atmosphere Packaging (MAP). We hope you find this article informative and beneficial. See you in our next article!