The Significance of Flame Temperature in MAPP Gas Applications

Related Articles: The Significance of Flame Temperature in MAPP Gas Applications

Introduction

With enthusiasm, let’s navigate through the intriguing topic related to The Significance of Flame Temperature in MAPP Gas Applications. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

- 1 Related Articles: The Significance of Flame Temperature in MAPP Gas Applications

- 2 Introduction

- 3 The Significance of Flame Temperature in MAPP Gas Applications

- 3.1 Understanding Flame Temperature

- 3.2 Factors Affecting MAPP Gas Flame Temperature

- 3.3 MAPP Gas Flame Temperature Compared to Other Fuels

- 3.4 Benefits of Using MAPP Gas

- 3.5 Applications of MAPP Gas

- 3.6 Safety Considerations with MAPP Gas

- 3.7 FAQs on MAPP Gas Flame Temperature

- 3.8 Tips for Using MAPP Gas Effectively

- 3.9 Conclusion

- 4 Closure

The Significance of Flame Temperature in MAPP Gas Applications

MAPP gas, a blend of methylacetylene and propadiene, is a versatile fuel widely used in various industrial and commercial applications. Its unique properties, including a high heat output and a relatively low flame temperature, make it a preferred choice for specific tasks. Understanding the flame temperature of MAPP gas is crucial for optimizing its performance and ensuring safe and efficient operation.

Understanding Flame Temperature

Flame temperature refers to the maximum temperature reached within a flame. It is a critical factor in various processes, including:

- Material Melting and Shaping: The flame temperature dictates the efficiency of melting and shaping materials, impacting the speed and quality of the process.

- Welding and Cutting: A specific flame temperature is necessary for achieving the desired weld penetration and cutting speed, while also minimizing distortion and heat damage to the surrounding material.

- Heat Treating: Precise flame temperature control is crucial for heat treating processes, ensuring proper hardening, annealing, or tempering of materials.

Factors Affecting MAPP Gas Flame Temperature

The flame temperature of MAPP gas is influenced by several factors, including:

- Gas Composition: The specific blend of methylacetylene and propadiene in MAPP gas directly affects its flame temperature.

- Air/Fuel Ratio: The proportion of air and fuel in the combustion process plays a significant role in determining the flame temperature. A lean mixture (more air) results in a lower flame temperature, while a rich mixture (more fuel) leads to a higher temperature.

- Gas Pressure: Higher gas pressure increases the flow rate, leading to a more intense flame and a higher flame temperature.

- Tip Size: The size of the torch tip influences the volume of gas released, impacting the flame size and temperature.

- Ambient Temperature: Lower ambient temperatures can slightly increase the flame temperature.

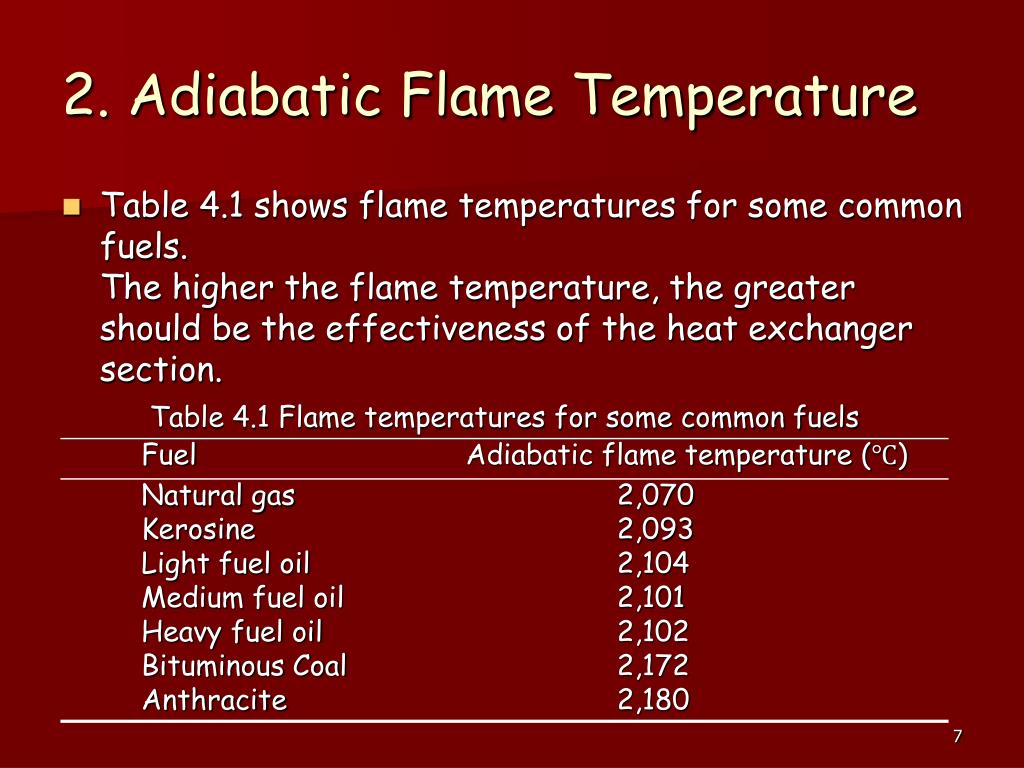

MAPP Gas Flame Temperature Compared to Other Fuels

MAPP gas boasts a higher flame temperature compared to propane and natural gas, making it an ideal choice for applications requiring intense heat. However, it falls short of acetylene’s flame temperature, which is the highest among commonly used fuels.

| Fuel | Flame Temperature (°C) |

|---|---|

| Acetylene | 3100 |

| MAPP Gas | 2900 |

| Propane | 1980 |

| Natural Gas | 1920 |

Benefits of Using MAPP Gas

The relatively low flame temperature of MAPP gas offers several advantages:

- Reduced Distortion: The lower heat input minimizes material distortion during welding and cutting processes, ensuring better dimensional accuracy.

- Less Heat Damage: The lower temperature reduces the risk of heat damage to surrounding materials, especially in delicate or sensitive applications.

- Improved Control: The lower flame temperature provides better control over the heat input, making it easier to achieve precise results in various tasks.

Applications of MAPP Gas

MAPP gas’s unique properties make it suitable for a wide range of applications, including:

- Welding: MAPP gas is commonly used for welding various metals, including steel, copper, and brass. Its high heat output and lower flame temperature ensure a strong weld without excessive distortion.

- Cutting: MAPP gas is effective for cutting steel and other metals, offering a faster and cleaner cut than propane.

- Brazing: The controlled heat of MAPP gas makes it ideal for brazing, a process used to join metal parts using a filler metal.

- Soldering: MAPP gas can be used for soldering, a process used to join electrical components or other metal parts.

- Heat Treating: MAPP gas can be used for heat treating processes, such as hardening, annealing, or tempering, to modify the properties of metals.

Safety Considerations with MAPP Gas

While MAPP gas is a versatile fuel, it is essential to handle it with care to ensure safety:

- Proper Ventilation: Ensure adequate ventilation when using MAPP gas to prevent the accumulation of potentially flammable gases.

- Use of Safety Equipment: Always wear appropriate safety equipment, including eye protection, gloves, and fire-resistant clothing, when working with MAPP gas.

- Storage and Handling: Store MAPP gas cylinders in a well-ventilated area, away from heat and ignition sources. Handle cylinders with care, using appropriate equipment to avoid damage.

FAQs on MAPP Gas Flame Temperature

Q: What is the optimal flame temperature for welding with MAPP gas?

A: The optimal flame temperature for welding with MAPP gas depends on the specific metal being welded and the desired weld penetration. A neutral flame, which is a balance between fuel and air, is generally recommended for most welding applications.

Q: Can the flame temperature of MAPP gas be adjusted?

A: Yes, the flame temperature can be adjusted by altering the air/fuel ratio. A lean mixture (more air) will lower the flame temperature, while a rich mixture (more fuel) will increase it.

Q: Is MAPP gas suitable for all welding applications?

A: MAPP gas is suitable for many welding applications, but it may not be the best choice for all. For example, acetylene is often preferred for welding thicker materials due to its higher flame temperature.

Q: How does the flame temperature of MAPP gas compare to propane?

A: MAPP gas has a significantly higher flame temperature than propane, making it more suitable for tasks requiring intense heat.

Q: What are the potential risks associated with using MAPP gas?

A: MAPP gas is a flammable gas, and it can pose a risk of fire or explosion if not handled properly. Always follow safety guidelines and use appropriate equipment when working with MAPP gas.

Tips for Using MAPP Gas Effectively

- Use the Correct Tip Size: Selecting the appropriate torch tip size is crucial for achieving the desired flame temperature and controlling the heat input.

- Adjust the Air/Fuel Ratio: Adjust the air/fuel ratio to achieve the desired flame temperature and characteristics.

- Pre-heat Materials: Pre-heating materials before welding or cutting can improve the efficiency of the process and reduce the risk of distortion.

- Use a Flame Shield: A flame shield can help protect surrounding materials from heat damage during welding or cutting.

- Monitor Flame Temperature: Regularly monitor the flame temperature to ensure it remains within the desired range.

Conclusion

MAPP gas’s unique flame temperature characteristics make it a versatile fuel for various industrial and commercial applications. Understanding the factors influencing its flame temperature and the benefits it offers is crucial for optimizing its performance and ensuring safe and efficient operation. By adhering to safety guidelines and utilizing proper techniques, MAPP gas can be a valuable tool for a wide range of tasks, from welding and cutting to brazing and heat treating.

Closure

Thus, we hope this article has provided valuable insights into The Significance of Flame Temperature in MAPP Gas Applications. We thank you for taking the time to read this article. See you in our next article!