The Vital Partnership: Map Gas and Oxygen in Industrial Applications

Related Articles: The Vital Partnership: Map Gas and Oxygen in Industrial Applications

Introduction

With great pleasure, we will explore the intriguing topic related to The Vital Partnership: Map Gas and Oxygen in Industrial Applications. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Vital Partnership: Map Gas and Oxygen in Industrial Applications

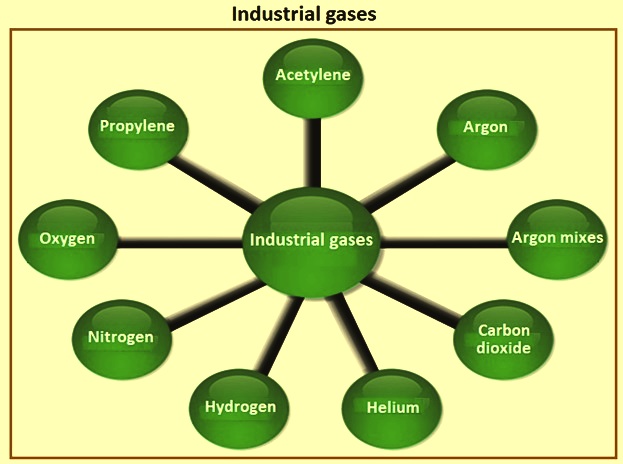

The world of industrial processes relies on a complex interplay of various gases, each with specific properties and applications. Among these, a unique and vital partnership exists between "map gas" and oxygen. This article delves into the nature of this partnership, exploring the characteristics of each gas, their individual roles, and the synergistic benefits they offer when used together in various industrial applications.

Understanding Map Gas: A Blend for Versatility

"Map gas" is not a singular gas but a carefully formulated blend of gases, typically comprising a mixture of propane, propylene, and butane. This carefully balanced composition provides map gas with a unique set of characteristics that make it highly valuable in numerous industrial processes.

Key Properties of Map Gas:

- High Heat Content: Map gas possesses a high heat content, making it an efficient fuel source for various applications requiring intense heat, such as welding, cutting, and brazing.

- Controlled Flame: The blend of gases in map gas produces a stable and controllable flame, allowing for precise control over the heat application and minimizing unwanted heat distortion in materials.

- Versatility: Map gas’s composition can be adjusted to suit specific applications, providing a customizable solution for various industrial needs.

- Cost-Effectiveness: Map gas is often more cost-effective than pure propane or other fuel gases, making it an attractive option for large-scale industrial operations.

Oxygen: The Essential Partner

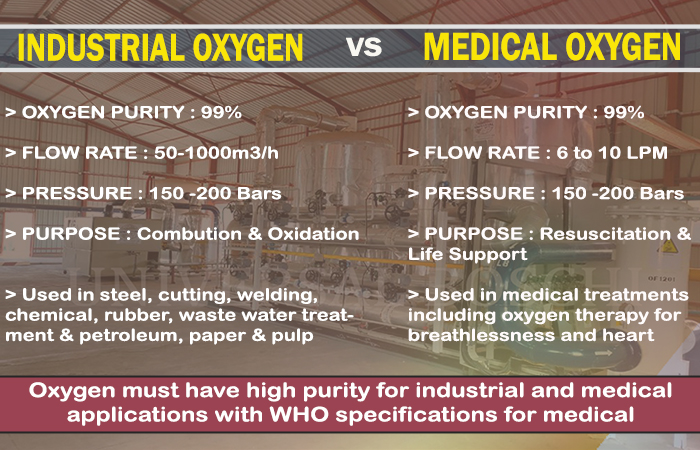

Oxygen, a highly reactive gas, plays a crucial role in various industrial processes, particularly those involving combustion and oxidation reactions. Its presence significantly enhances the efficiency and effectiveness of these processes.

Key Properties of Oxygen:

- Increased Combustion Efficiency: Oxygen’s high reactivity accelerates combustion reactions, resulting in higher temperatures and more efficient energy utilization.

- Enhanced Cutting and Welding: In combination with map gas, oxygen facilitates faster and cleaner cutting and welding processes, improving productivity and material quality.

- Oxidizing Agent: Oxygen acts as an oxidizing agent, promoting the formation of oxides, a crucial aspect in various industrial processes like metal refining and chemical synthesis.

The Synergistic Partnership: Map Gas and Oxygen in Action

The combination of map gas and oxygen creates a powerful force in numerous industrial applications, offering a synergistic effect that surpasses the capabilities of each gas individually.

Key Applications of Map Gas and Oxygen:

- Welding and Cutting: This combination is the cornerstone of metal fabrication, enabling precise cutting and welding of various materials. The heat generated by the burning map gas, combined with the oxidizing power of oxygen, creates a powerful cutting torch or welding flame.

- Heat Treating: Oxygen-enriched map gas flames are used for heat treating metals, altering their properties to improve hardness, strength, or ductility.

- Glassblowing: Map gas and oxygen are used in glassblowing to control the temperature and flame characteristics, allowing skilled artisans to create intricate glass objects.

- Chemical Processing: The combination of map gas and oxygen is utilized in various chemical processes, including oxidation reactions and synthesis of new materials.

Benefits of Using Map Gas and Oxygen Together:

- Increased Productivity: The faster combustion rates and enhanced heat transfer achieved with oxygen-enriched map gas lead to significantly higher productivity in various industrial processes.

- Improved Material Quality: The controlled flame and oxidizing power of oxygen-enriched map gas result in higher quality welds, cuts, and heat-treated materials.

- Reduced Energy Consumption: The increased efficiency of combustion reactions achieved with oxygen-enriched map gas reduces overall energy consumption, contributing to cost savings and environmental sustainability.

- Enhanced Safety: The controlled flame and precise heat application of oxygen-enriched map gas contribute to a safer working environment, minimizing the risk of accidents and injuries.

FAQs about Map Gas and Oxygen

Q: What are the safety precautions to consider when using map gas and oxygen?

A: Map gas and oxygen are flammable gases and should be handled with utmost care. Always store and transport these gases in designated cylinders and ensure proper ventilation in the working area. Never mix map gas and oxygen in the same cylinder or container. Always use appropriate personal protective equipment, including safety glasses, gloves, and fire-resistant clothing.

Q: How do I choose the right mixture of map gas and oxygen for my specific application?

A: The optimal mixture of map gas and oxygen depends on the specific application, material being processed, and desired results. Consult with a gas supplier or a qualified expert to determine the appropriate mixture for your needs.

Q: What are the environmental considerations associated with using map gas and oxygen?

A: While map gas and oxygen are not inherently harmful to the environment, their use can generate emissions during combustion. It is essential to use these gases responsibly, minimizing waste and emissions. Consider using fuel-efficient equipment and adopting sustainable practices to reduce environmental impact.

Tips for Using Map Gas and Oxygen Safely and Effectively:

- Use only certified equipment: Ensure all equipment, including cylinders, regulators, hoses, and torches, are certified for use with map gas and oxygen.

- Inspect equipment regularly: Regularly inspect all equipment for leaks, damage, or wear and tear. Replace or repair any faulty components promptly.

- Train personnel properly: Ensure all personnel handling map gas and oxygen are properly trained in safety procedures, equipment operation, and emergency response.

- Follow manufacturer’s instructions: Always adhere to the manufacturer’s instructions for handling, storage, and use of map gas and oxygen.

- Store cylinders securely: Store map gas and oxygen cylinders in a well-ventilated area, away from heat sources and direct sunlight. Secure cylinders to prevent accidental toppling.

Conclusion: A Vital Partnership for Industrial Progress

The partnership between map gas and oxygen has revolutionized various industrial processes, driving innovation and efficiency across diverse sectors. Their unique properties, when combined, create a powerful force that facilitates faster, more precise, and more efficient operations. From metal fabrication to chemical processing, the synergy between these gases continues to play a vital role in shaping the future of industry. As technology advances, the role of map gas and oxygen in industrial applications is likely to expand further, driving innovation and progress across the globe.

Closure

Thus, we hope this article has provided valuable insights into The Vital Partnership: Map Gas and Oxygen in Industrial Applications. We appreciate your attention to our article. See you in our next article!